Tell Me More

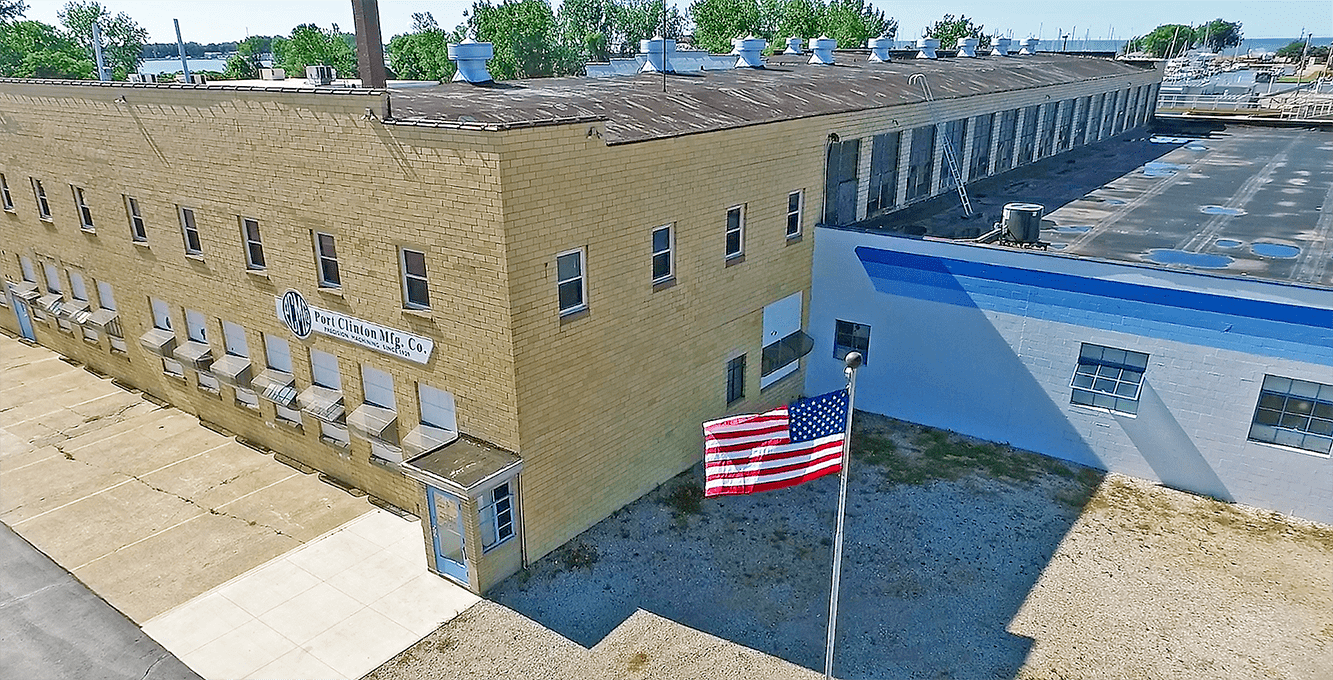

PCM has long provided its customers with a full range of in-house machining capabilities. This broad range of machining, top notch quality processes and systems, as well as the sizable capacity of the plant, sets Port Clinton Manufacturing apart from its competitors. With 68,000 square feet of manufacturing capacity, Port Clinton Manufacturing Co. can support the most demanding quality and Just-In-Time requirements its customers may have.

Railroad

Oil and Gas mining

Emergency Power Generation

Off highway – Agricultural and construction

Mine safety devices

Heavy truck transmission

Brake system components

Brake system components

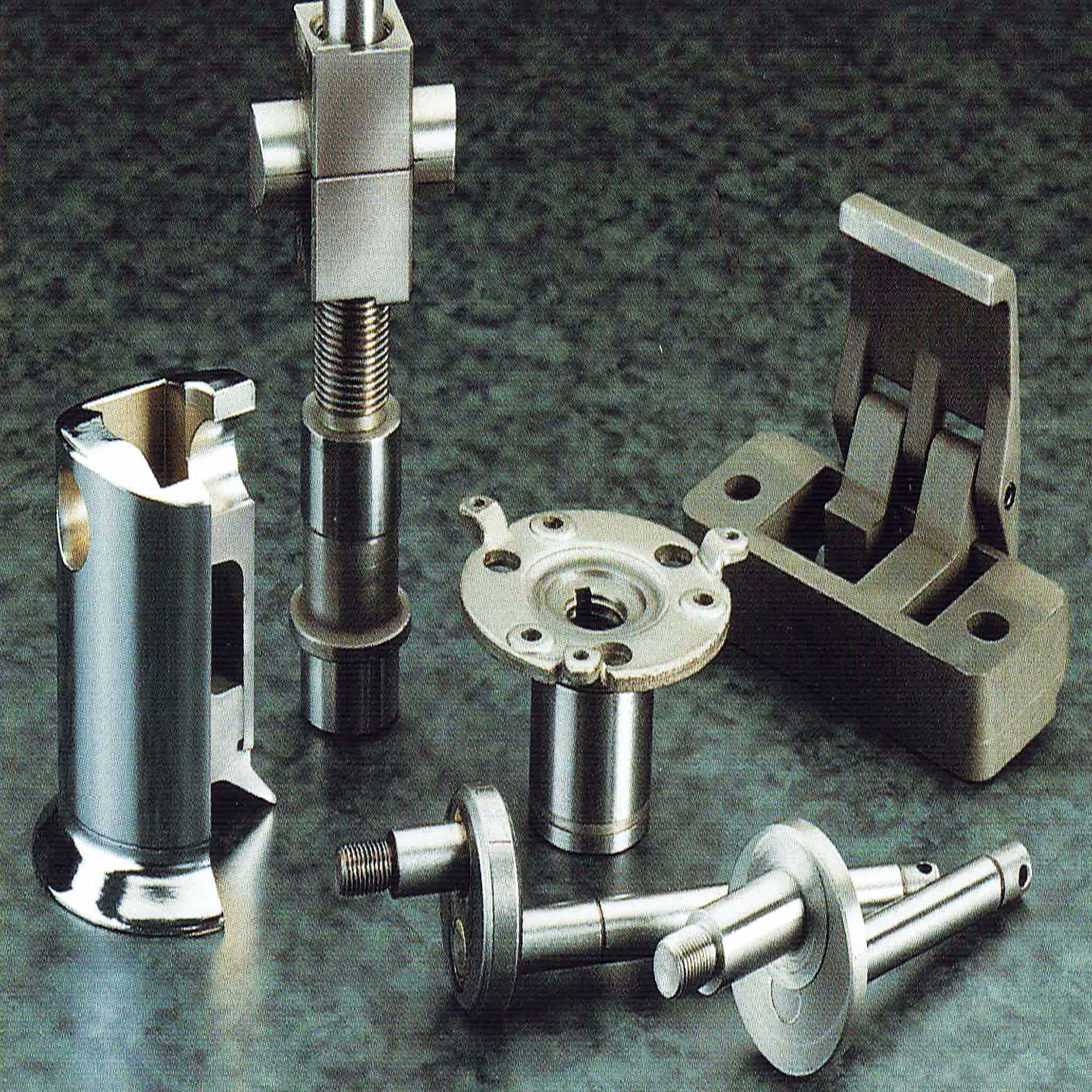

Beginning with customer blueprints and or design concepts, PCM’s experienced staff determines the most efficient way to machine each part. In addition, PCM assists each customer in finding unique solutions to their machining requirements. In every case, close attention to cost is always observed.

PCM has considerable experience in producing high class precision moving parts and will be happy to assist customers with prototyping, material selection, dimensioning, tolerancing, heat treating, as well as value engineering parts to reduce cost while maintaining functionality. This service is especially relevant with producing mating parts and assemblies.

At the heart of our plant is the primary machining department which consists of 25 automatic screw machines with capacities through 3' 1/2" . A variety of other equipment including CNC Lathes, are available for this initial turning of a part.

PCM has an extensive network of heat treaters and coating experts to impart properties and provide final coating for all of our customers parts. This service and network is part of PCM’s process. Customers can get full service and only deal with one supplier.

PCM has complete secondary machining capability for both work that is done as part of a complete component or assembly and also completes secondary work operation as stand alone jobs. Secondary work including: Grinding, Thread roll, Knurling, Chucking (CNC and Multi Spindle, Drill and Tap, Cross drill and deep hole drill Counter sink, Precision Assembly, Broaching, Honing Milling, Tumbling, Bead blast, Cut to length, Grooving, Slotting, Trimming, Chamfering

Many PCM manufactured parts come into existence in one of some 25 multi-spindle bar machines others come in as blanks from casting houses and cold headers. As necessary, PCM can chuck blanks up to 12” diameters on CNC or Multiple Spindle Chuckers.

Because most of PCM’s work is done to very close tolerances, the Grinding Department is a key area. PCM is equipped to form grind I.D., O.D grind, centerless grind, double disk grind, and Blanchard Grind to very close finish tolerances.

Broaching is by far the most economical and efficient way of not only producing splines and slots, but also to contour surfaces inside and out as well as correct hole geometry Long a strength of the company, PCM’s broaching department is equipped with 12 machines and can work internally and externally to the limits of our 54" stroke, 15 ton machine. This means, "we can broach anything we can turn."

More than making individual parts, PCM specializes in mating parts together through various methods including brazing and mechanical fits producing a precision assembly for additional machining or ready for assembly.

This is where our plant's diverse capabilities are used to their best advantage -- in providing assemblies of finished precision parts. Also, for engineering or economic reasons, in-process components may be assembled and then machined to finish tolerances. In either case, by performing the work, "in-house", we provide "ready to use" components at very competitive prices.

As a tier 1 supplier to major engine manufacturers, PCM has developed and implemented a top notch quality program. The company offers PPAP service and is able to accurately measure all required part dimensions. The company has developed cleanliness testing and is able to meet customer ever increasing demands on quality and quality documentation

- CMM

- Profile measurement

- Computerized Surface Profile

- Optical Comparator

- Surface finish testing

- Magnaflux testing

- Rockwell hardness testing

- World class calibration process

- Ultrasonic cleaning and Millipore testing including particle counting

Always locally owned and operated as a family business, Port Clinton Manufacturing prides itself on outstanding customer service and support. This is evidenced by the fact that several fortune 500 companies have been with PCM for over 50 years. Not many companies can make this statement, however the principles are basic: A long standing reputation of integrity, Fair dealing, And being a responsible corporate citizen in a small town

Once a job is started and proven out, the company then continuously searches for ways to improve the manufacturing efficiency to both reduce cost and ensure product quality

Screw Machining Companies Chardon Metal Products Gent Machine Co Ramble Machine Forest Machine Products Co. Ohio Metal Products Premier Machine Products Ashley Ward, Inc Keystone Threaded Products Worldwide Chuck Services Lansco Manufacturing McNeil Industries Triaxis Machine & Tool Automatic Parts, Mansfield OH Matrix Tool & machine Midwest Precision LLC No Limit Swiss Bowden Manufacturing Corp Dalton Consulting Group Climax Metal Products Elgin Fasener Group Maumee Valley Fab Inc Bruck Manufacturing Co. Kelko Swartz Manufacturing Kernell’s automatic Machining Duffin Mfg. Toledo Screw Products Federal Automatic Screw Machines Micron Manufacturing Standby Screw Machine Products Cleveland Screw Products Bay Mfg. Mel-Ba Mfg Lehner Screw Machine CO. Ohio Screw Products EMC Screw Products Superior Products Inc. Precision Grinding Grinding Grind All, Inc Alternative Surface Grinding Corp Astro Manf. & Design F. M. Machine Co. Euclid Precision Grinding Co. Ashley Ward, Inc. Jerpbak-Bayless Co. Aerotech Enterprises Lee’s Grinding, Inc SC Industries EPG Masters, LLC Global Precision Parts Action Precision Products The Prince & Izant Companies Universal Grinding Corp. Schwab Machine S & B Metal Products Panic Precision Grinding Mel-Ba Mfg. Myers Precision Grinding H & B Machine & Tool Co. Jamar Lange Grinding Barile Precision Grinding Rochester Mfg Grother Machine Co.